This machine stands out for its robustness and reliability, even when dealing with the hardest and most abrasive materials.

Even though its developed to meet the same stringent requirements as the larger REV series, it features compact transport

dimensions of 2.5 meters in width and 3.4 meters in height, with a weight of only 34 tonnes. The two-deck pre-screen “Grizzly”

,that this machine is equipted with, ensures efficient pre-separation of low-grade material before it reaches the crusher.

Additionally, the jaw crusher can be equipped with an optional hydraulic protection system (HPS), which guarantees trouble-free operation if uncrushable material such as excavator teeth or iron girders enters the crushing chamber. The GCR100

ensures reliable performance even under the most diverse and demanding operating conditions.

Optional

''HPS'' Hydraulic protection for crusher against uncrushable material

Magnetic Overband

Dust suppression system

Automatic greasing unit

Deflector plate under crusher

Electric diesel fueling pump

Reverse crusher

| Inlet dimensions (mm) | 1015x650 |

| CSS adjustment (mm) | 20-120 |

| Crusher weight (kg) | 13000 |

| Vibrating Feeder | |

| Width (mm) | 900 |

| Length (mm) | 2400 |

| Prescreen Grizzly | |

| Width (mm) | 1000 |

| Length (mm) | 1500 |

| Decks | 2 |

| Main conveyor | |

| Width (mm) | 800 |

| Length (mm) | 9700 |

| Reversible conveyor | |

| Width (mm) | 750 |

| Length (mm) | 1700 |

| Side discharge conveyor | |

| Width (mm) | 500 |

| Discharge height (mm) | 1990 |

| Track | |

| Length (mm) | 4200 |

| Panel width (mm) | 450 |

| Engine | |

| Power (kW) | 168 |

| Performance | |

| Max feeding size (mm) | 600 |

| Hourly production ton/h | up to 180 |

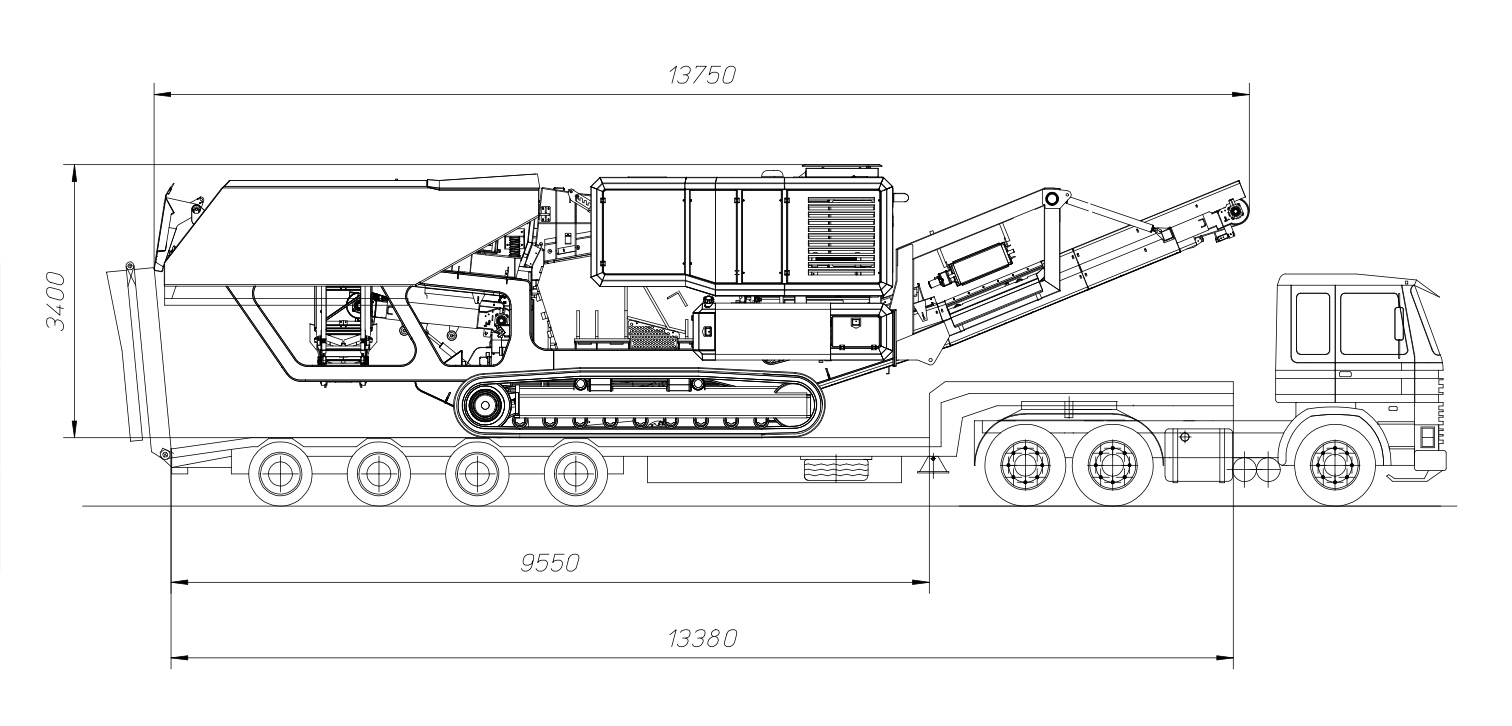

Transport dimensions

| Length (mm) | 13750 |

| Width (mm) | 2500 |

| Height (mm) | 3400 |

Working dimensions

| Length (mm) | 14800 |

| Width (mm) | 2570 |

| Height (mm) | 4040 |