Specialist in

crushing and

screening

Development of customized systems based on customer needs.

Discover the Technology Inside Our Machines

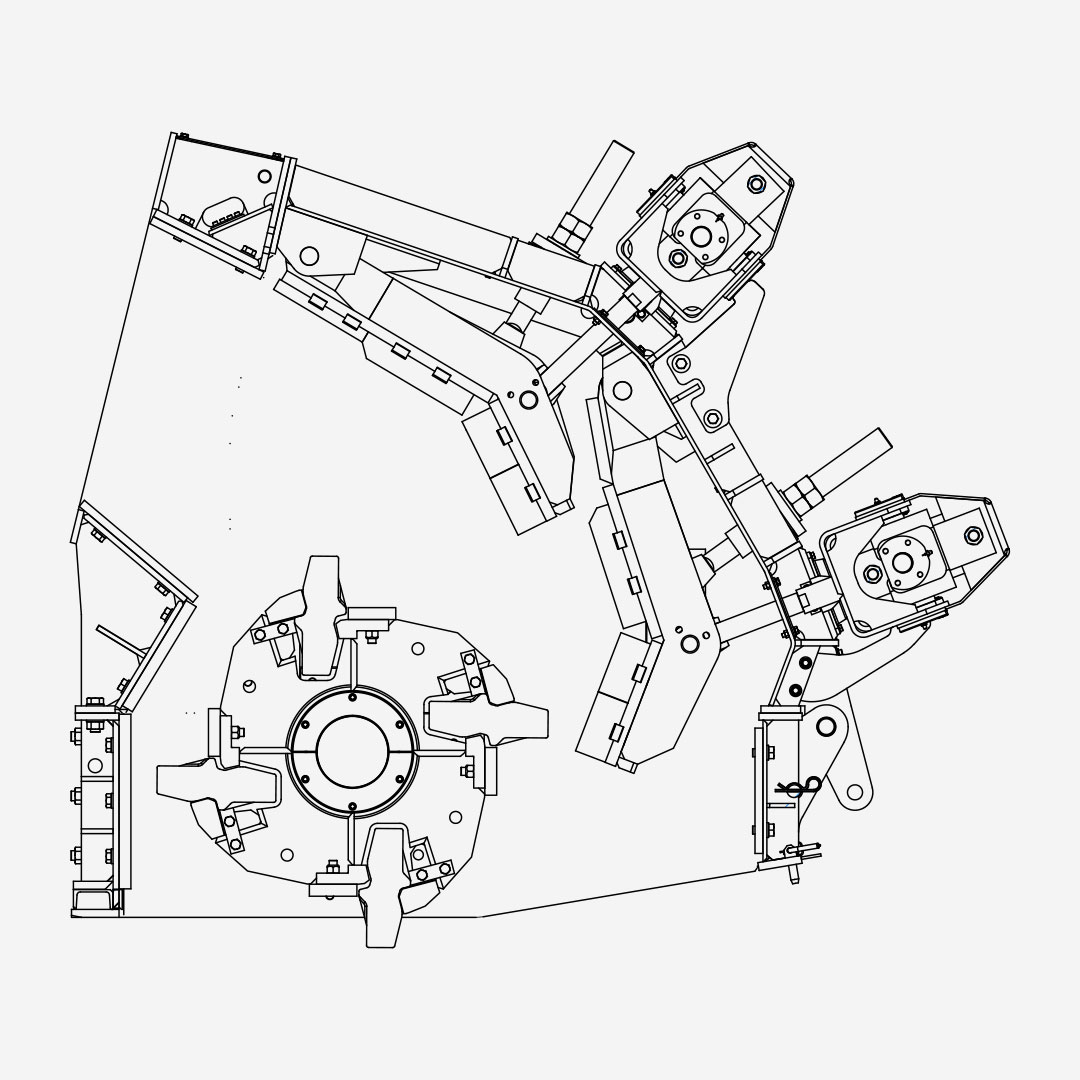

Hartl Impactor

The Hartl Impactor is an advanced impact mill designed for efficient material processing. Equipped with a hammer rotor, this mill utilizes robust hammers to crush various materials within its precision-engineered crushing chamber, ensuring optimal performance and reliability.

Crushing solutions for all material types

Whether it’s concrete, construction debris, rock, or waste, our advanced machinery is equipped to handle even the most demanding tasks. From quarries to demolition sites, our solutions ensure efficient material processing, delivering exceptional performance in every project.

Crushing solutions for all material types

Whether it’s concrete, construction debris, rock, or waste, our advanced machinery is equipped to handle even the most demanding tasks. From quarries to demolition sites, our solutions ensure efficient material processing, delivering exceptional performance in every project.

Looking for Expert Assistance?

Our team of highly qualified technicians is always on hand to provide expert support, answer your questions, and help you resolve any issues you may encounter.

+39 0541 928474

News

Events, fairs and news.

50 years of history.

Founded in 1967, our company traces its roots back to 1952, when the first production unit became operational. Building on the legacy of their father, a skilled blacksmith in a small farming community in the province of Pesaro Urbino, brothers Ettore and Roberto Vignali continue to lead the company with the same dedication to craftsmanship and innovation.

Digitization of warehouse logistics, production bills of materials, and time tracking. Synchronization of plant data for post-sales management.

The company upgraded its hardware for logistics and production management, including bills of materials, time tracking, and support services. The new equipment includes servers, switches, access points, PCs, printers, and scanner guns. The consulting services covered logistics, production launch via bills of materials, production orders, time tracking, and the integration of data transmitted from Movimatica control units.